GMC 35 ISM

GMC 35 ISM

CNC數控6軸自動車床:擁有先進CNC數控技術的全部優點

.jpg)

GMC 35 ISM是GM系列自動車床中可加工直徑35 mm的機型。由于它靈活性好和精度高,即使中等批量也能高效生產。該機新特性是兩個精加工位的X軸滑座都為直線電機驅動。 GMC 35 ISM進入CNC數控多主軸機床的新領域。GMC 35 ISM的整體優勢為該機提供全面生產能力,適應3-35 mm直徑各種批量大小的生產要求。單分度主軸滾筒一項就能縮短周期時間。并且新開發的MF Programmer 3D軟件進一步推動多主軸機床的成功。

Highlights GMC 35 ISM

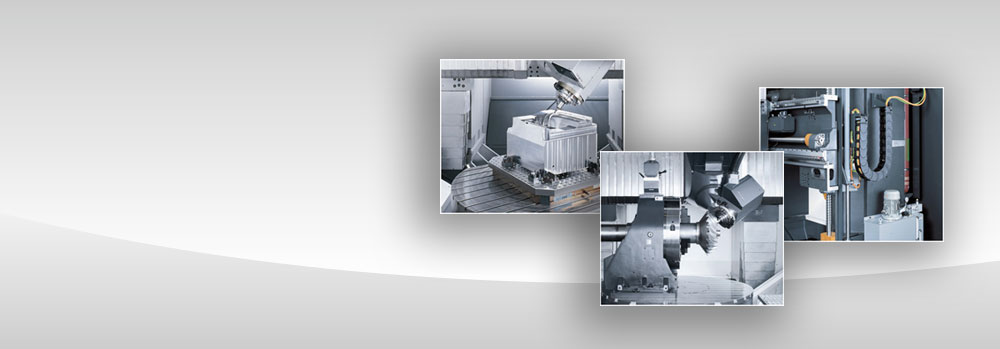

- 加工區與凸輪控制的機床類似,傳統機床操作人員培訓簡單。

- 動態性能好和結構穩定,與機械式多主軸機床的周期時間等同。

- 6個帶油冷獨立的主軸電機

- 標配5個CNC復合中心架,切斷刀架和背面加工刀架。

- 內徑和外徑加工精度高,公差H5

- 扭矩穩定的同步主電機

- 連續分度主軸滾筒,大限度縮短非加工時間

- 排屑好,通過CNC數控導向架支撐工件

- DMG Programmer 3D Turning編程容易和程序無碰撞

.jpg)

.jpg)

技術參數

GMC 35 ISM

機床型號 |

|

GMC 35 ISM |

|

加工區 |

|

|

|

Max. bar passage |

mm |

35 |

|

Max. bar feed / component length |

mm |

140 |

|

Number of main spindles |

|

6 |

|

主軸環直徑 |

mm |

280 |

|

Drum switching time |

mm |

1 |

|

Main spindle |

|

|

|

One drive for all six main spindles with C-axis (0.001°) |

rpm |

- |

|

Six integrated spindle motors (ISM) with C-axis (0.001°) |

rpm |

6,000 |

|

Drive power / Torque (40%) |

kW // Nm |

18.6 / 42.7 |

|

Frontal spindle* and pickup spindle |

|

|

|

Separate drive for each spindle position with C-axis (0.001°) |

rpm |

6,000 |

|

Drive power / Torque (40%) |

kW // Nm |

10 / 47.8 |

|

Frontal machining: frontal spindle positions 1-5 |

|

|

|

Frontal slide travel W1-W5 (standard) |

mm |

180 (220)* |

|

Frontal slide travel W1-W5 (high performance)* |

mm |

180 |

|

Acceleration W1-W5 (standard / high performance) |

m/s2 |

10 / 7 |

|

Rapid traverse speed W1-W5 (standard / high performance) |

m/min |

30 / 21 |

|

Feed power W1-W5 (standard / high performance) |

kN |

3.7 / 8.5 |

|

U-axis* travel positions 4 and 5 (positions 1 to 5 from GMC 35 ISM) |

mm |

23 |

|

Rear-sided machining: pickup spindle, position 6 |

|

|

|

Front slide travel W6 |

mm |

220 |

|

Acceleration W6 |

m/s2 |

10 |

|

Rapid traverse speed W6 |

m/min |

30 |

|

Feed power W6 |

kN |

3.7 |

|

Driven* tools |

|

|

|

Number of driven tool axes (multiple tools can be used) |

Number / rpm |

6 / 6,000 |

|

Drive power / Torque (40%) |

kW // Nm |

3.8 / 7 |

|

Radial machining: cross slides, positions 1 to 5 |

|

|

|

Axis travel X1, X2, X3, X4, X5 |

mm |

80 |

|

Axis travel Z1, Z2, Z3, Z4, Z5 |

mm |

100 |

|

Acceleration X1-X5 / Z1-Z5 |

m/s2 |

10 |

|

Rapid traverse speed X1-X5 / Z1-Z5 |

m/min |

30 |

|

Feed power X1-X5 / Z1-Z5 |

kN |

3.1 / 3 |

|

Y-axes* travel (only possible for positions 3 to 5) |

mm |

35 |

|

Rapid traverse speed Y3-Y5 |

m/min |

15 |

|

Feed power Y3-Y5 |

m/min |

1.7 |

|

Radial machining: two lateral slides, position 6 |

|

|

|

X6 and U6 travel |

mm |

120 |

|

X6 and U6 acceleration |

m/s2 |

10 |

|

X6 and U6 rapid traverse speed |

m/min |

30 |

|

X6 and U6 feed power |

kN |

1.2 |

|

Z6* travel |

mm |

4 |

|

Central block |

|

|

|

Central block* travel W7 |

mm |

100 |

|

Hydraulic bar stop* |

mm |

18-254 |

|

機床 |

|

|

|

機床占地面積包括排屑器 |

m2 |

- |

|

排屑器排屑高度 |

mm |

- |

|

機床高度 |

mm |

- |

|

機床重量 |

kg |

13,100 |

* Optional

控制系統 |

|

DMG MORI SLIMline®控制面板帶Siemens 840D powerline,雙CPU |